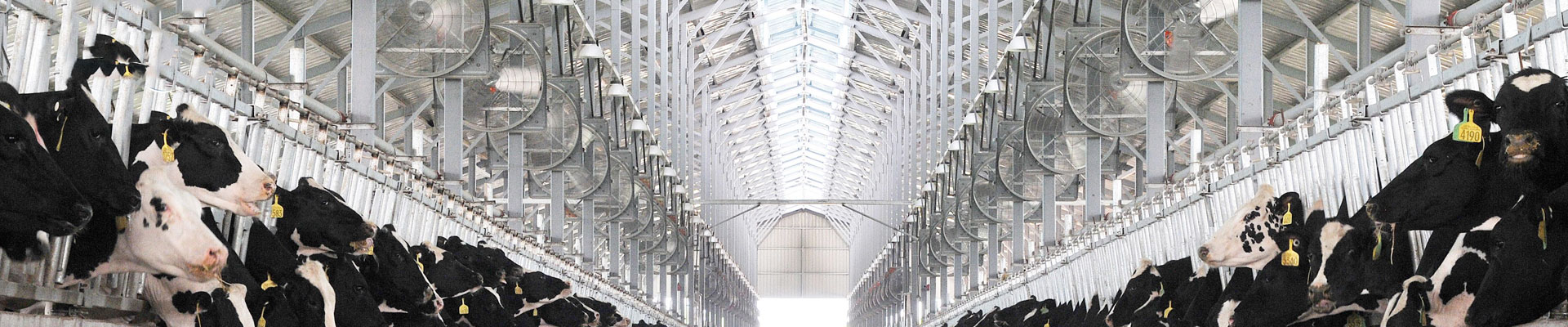

The maintenance of negative pressure fans should pay attention to three aspects:

First, for the care and maintenance of the motor

1 Disconnect the main power supply and check whether the motor grounding wire is good.

2. Tighten the screws and couplings of each part.

3. Check whether the insulation resistance of the motor meets the regulations, and check the main circuit contacts. If the contacts are severely ablated (the contact points are worn to 1/3 of the original thickness), the contacts should be replaced.

Note: When repairing, a sign should be hung on the power supply to inform people that it is being repaired

Maintenance of the damper:

1. Adjust the tightness of the belt, move the wind wheel by hand, and observe whether the rotation is stable.

2. Check and replace the gasket and sealing packing between the joint surfaces.

3. Clean the inside of the motor, wind wheel, filter and casing. The paint should be repaired where the paint has fallen off.

4. Fill the rotating parts with lubricating oil to make the coupling and bearing flexible and stable

3. Repair and maintenance of electrical circuits:

1. Check whether the mechanical opening and closing action of the control valve is flexible and clear.

2. Manually start on and check whether the indicator light and voltage and ammeter are working normally, whether there is any abnormal sound in the operation of each part of the fan, and whether the three-phase current value is balanced.

3. Check whether the components in the control box of each remote control point are normal.

4. Start and stop the machine three times in a row to check whether the remote control of each point is correct**.

5. After two hours of trial operation, observe whether the temperature of the motor bearing and the increase in the temperature of the motor are normal. Make the fan run normally.

For the negative pressure fan, regular maintenance should be carried out every six months, and the situation should be recorded to make the negative pressure fan run well.

+86-4000-536-552

+86-4000-536-552