Product Description

● Performance features

The fan is directly connected to the blade, making the motor power transmission efficiency higher.

With strong connection, it eliminates the belt wear and it is convenient to use.

It reduces the intermediate links of power transmission and its operation is stable with high air volume.

The shell adopts the one-time injection molding process with high strength.

The fan is directly connected to the blade, making the motor power transmission efficiency more stable.

With strong connection, it eliminates the belt wear and it is convenient to use.

The fan is directly connected to the blade, making the motor power transmission efficiency higher.

It has no belt wear and it is convenient to use.

The shell adopts the one-time injection molding process.

The fan is directly connected to the blade, making the motor power transmission efficiency more stable.

It has no belt wear and it is convenient to use.

The blade is made of the mirror stainless steels through molding; press forming and it has large air volume without deformation, fracture and ash. It is attractive and durable;

The motor is directly connected with the fan blade, so that the power transmission efficiency of the motor is higher.

There is no belt wear, and it is easy to use.

The intermediate link of power transmission is reduced, and the operation is stable and the air volume is large.

The shell adopts the one-time injection molding process.

The fan is directly connected to the blade, making the motor power transmission efficiency more stable.

It has no belt wear and it is convenient to use.

The blade is made of the mirror stainless steels through molding; press forming and it has large air volume without deformation, fracture and ash. It is attractive and durable;

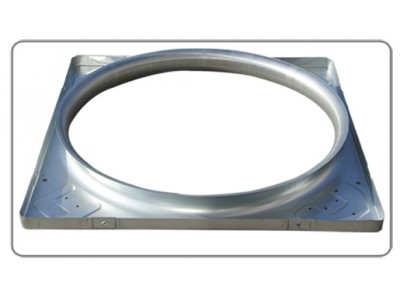

The fan shroud is made of a galvanized layer of 275 g/square, which increases the thickness of the galvanized layer to ensure that it will not rust in the future; The design of reverse flow along the valgus edge is adopted to improve the ventilation volume, reduce the vibration and noise of the fan, and increase the stability of the fan;

According to customer needs, the annular hoisting ring can be installed and used to facilitate customer installation;

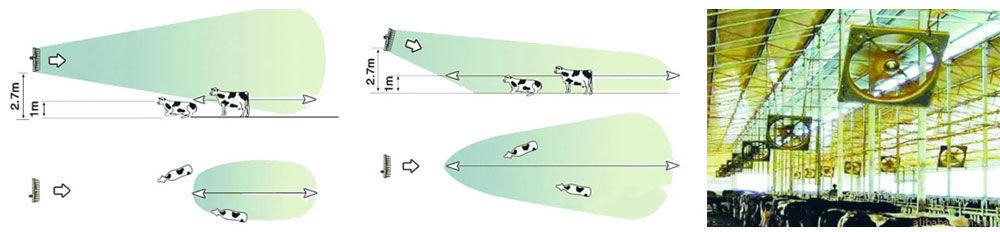

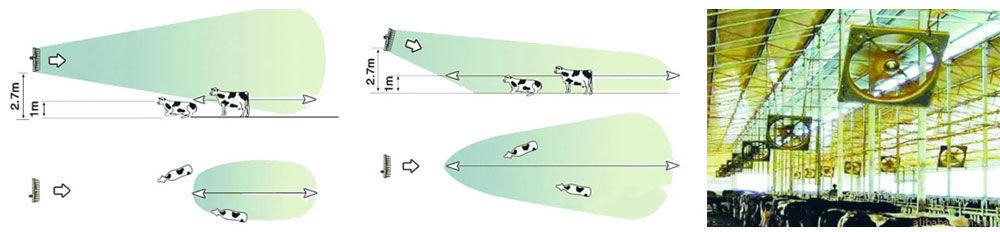

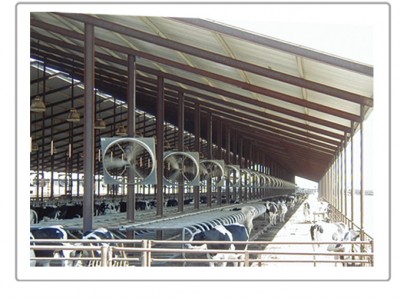

In order to achieve good ventilation, the fan is installed directly above the cowshed trough, the lower edge of the fan is 2.7 meters from the ground, and the tilt angle is 15 to 30 degrees.

+86-4000-536-552

+86-4000-536-552